The Incredible Science Behind Sheet Metal Fabrication

Sheet metal fabrication is an art, a science, and a testament to human ingenuity. It is a process that molds, cuts, and shapes metal materials into specific parts and structures. It’s a world of stainless steel, metal parts, and complex processes, all working in perfect harmony to create something truly remarkable.

At its core, sheet metal fabrication is the process of transforming flat sheets of aluminum or steel into specific shapes for use in manufacturing. It’s the magic that turns a flat piece of metal into something functional and practical. Imagine a world without cars, airplanes, or even your kitchen appliances. Hard to picture, right? That’s the power of sheet metal fabrication.

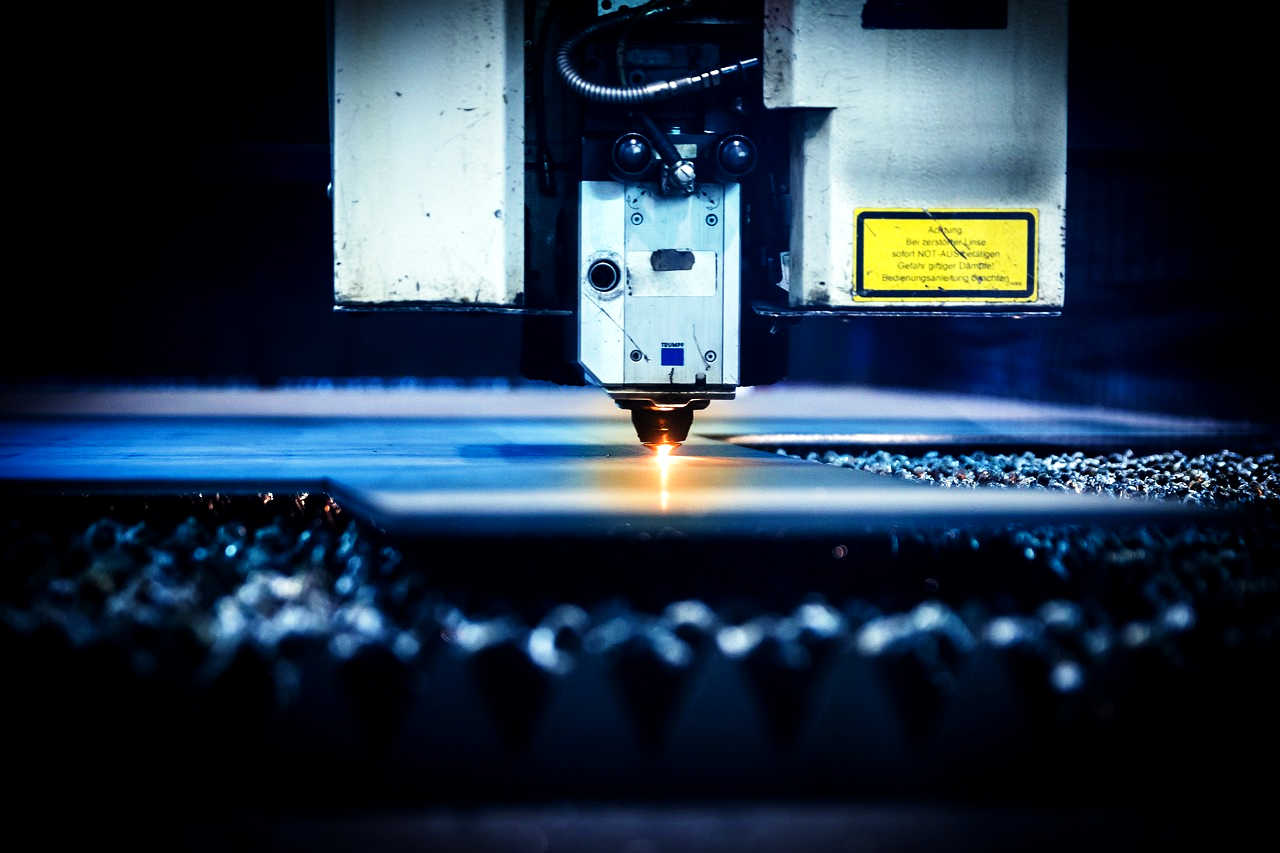

Let’s delve deeper into the fabrication process. It typically starts with cutting. Large sheets of metal are trimmed down into smaller pieces using laser cutting machines. These machines are highly precise, ensuring that each piece is cut according to the exact specifications required.

Bending and Forming: Shaping the Metal

Next comes bending or forming. This is where the cut metal pieces are shaped into the desired form. It can be a complex curve for a car part, a sturdy angle for a building structure, or a subtle fold for your kitchen utensils. Metal fabricators accomplish this through CNC machining, a process that uses pre-programmed software to control the movement of machinery and tools.

- Bending or Forming Process: This is the stage where the previously cut metal pieces are modified into the desired shapes, which can range from intricate curves to robust angles, depending on the end product.

- Versatility of Shapes: The bending or forming process can create a variety of shapes, whether it’s a complex curve for automotive parts, a strong angle for architectural structures, or a delicate fold for kitchen utensils.

- Role of Metal Fabricators: It is the metal fabricators who execute this transformation, shaping the cut metal into the required form using expert skills and specialized machinery.

- Use of CNC Machining: CNC machining plays a crucial role in this stage of sheet metal fabrication. This technology uses pre-programmed software to control the movement of machinery and tools, ensuring precision and consistency in the shaping process.

- Software-guided Precision: The use of CNC machining not only enhances the precision of the final product but also allows for the creation of complex and intricate designs that would be difficult to achieve manually. This increases the range and complexity of products that can be produced through sheet metal fabrication.

Beyond Cutting and Shaping

Beyond bending and shaping, there are more processes involved. There’s injection molding, a manufacturing method used to produce intricate parts in large volumes. And let’s not forget powder coating, a type of coating that is applied as a free-flowing, dry powder to create a hard finish that is tougher than conventional paint

Of course, the process doesn’t end there. Once the parts are cut and shaped, they have to be assembled. This is where welding comes in. Welding is the process of joining two metal parts together by melting the areas where they meet and adding a filler material that cools to form a strong joint.

Sheet metal fabrication is an art in itself. It requires a blend of technical skill, precision, and an understanding of materials and processes. It’s the unsung hero of the manufacturing world, quietly shaping the metal parts that make up the machines and products we use every day.

By now, you probably have a better understanding of what sheet metal fabrication is. It’s a process that breathes life into the steel, transforming it from a simple sheet into something much more. It’s a testament to human creativity and innovation – a perfect blend of science, technology, and artistry.

The Heart of Manufacturing: A Testament to Human Ingenuity

Sheet metal fabrication is not just a process. It’s a testament to human ingenuity and craftsmanship. It’s a reminder of how far we’ve come, and a sign of the incredible things we can achieve when we combine our skills with the right tools and materials. It’s the heart of manufacturing, and it’s what keeps the wheels of industry turning.

Remember, every time you marvel at a well-structured building, a smoothly running car, or even a beautifully designed piece of kitchenware, you’re witnessing the magic of sheet metal fabrication. It’s a world full of metal, laser, and manufacturing brilliance – a world that we all benefit from every single day.

To sum it up, sheet metal fabrication is an essential process in our daily lives, driving innovation, and making our world a better place. So, the next time you see a piece of sheet metal, take a moment to appreciate the craftsmanship and technological prowess that went into its creation.